Final Project

Table of contents

I have two ideas

PassioGo Tracker

Inspired by MBTA tracker.

Inspired by MBTA tracker.

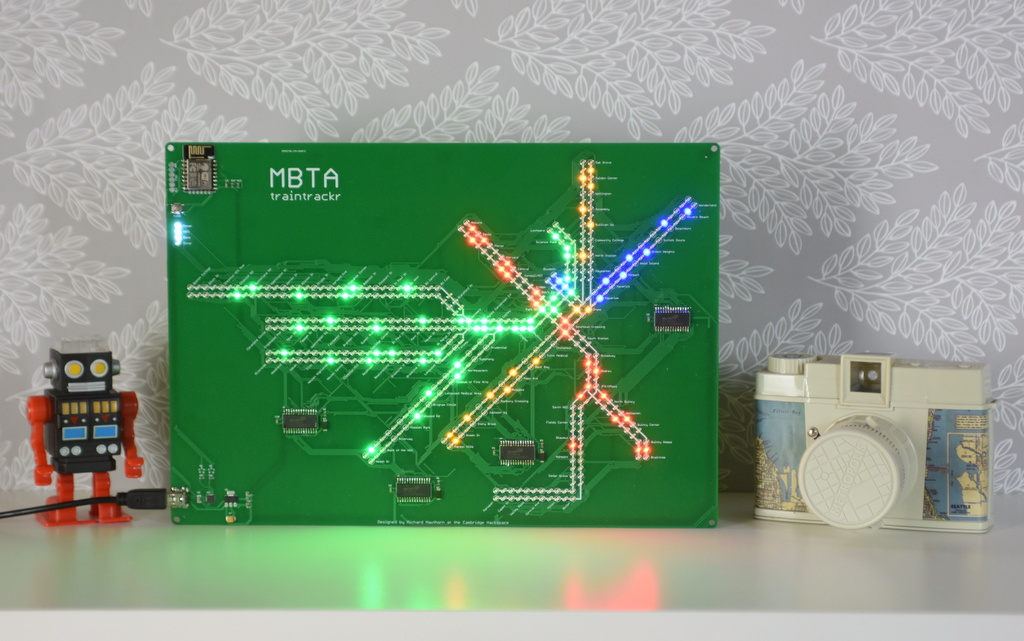

I came across this website TrainTrackr from a FB ad which tracks the MBTA trains in real time. I thought it would be cool to make a similar website for the Harvard Shuttle’s on PassioGo since the app is so bad.

Hydroponic Indoor Herb Greenhouse

I love cooking, and my number one biggest pet peeve is having to go to the grocery store to buy fresh herbs. It’s likely that I will continue to live in places without a garden, so it will be hard to grow my own herbs outside plus the climate in the north-east isn’t suited for year-round herbs. Oh, and I’m also really bad at taking care of plants, so whatever I try and grow has to be automated.

- Herbs go bad real fast and freezing them doesn’t really work.

- They’re kinda expensive (at least it adds up real fast) and you can’t get a good variety at the store.

- You always need a herb that you don’t want.

Aerogardens are kinda expensive (~$200), crowds easily and not very modular.

Aerogardens are kinda expensive (~$200), crowds easily and not very modular.

Specifications and goals

- Modular system - stack them vertically, each plant in it’s own container

- As automated as possible - microcontroller, sensors, grow lights + reflectors, water pumps, etc.

- Low maintenance

Bill of materials

- Microcontroller (reading sensors, controlling pumps, lights, etc.)

- Motor (for controlling the angle of the lights)

- Water pump (water flow) and air pump (oxygen)

- Various sensors, initial research suggests

- electrical conductivity probe

- pH sensor

- water temperature sensor

- air temperature/humidity sensor

- Grow lights and power supply

- Reflectors (Can be made through laser cutting and cheap reflective material)

- 3D printed parts (e.g. container to hold each plant)

- Small OLED/LCD screen

- PVC piping or large rectangular container (not important yet since the prototype will be small)

Project plan

- Design hydroponic system and research potential improvements over AeroGarden design (03/05/23)

- Prototype initial system design using available electronics and currently available or 3D printable parts. E.g. A small one-plant container with water pump, air-pump, and some sensors. (03/15/23)

- Design system and 3D print parts (03/15/23)

- Get initial circuit and microcode written for the system (03/15/23)

- Test with small easy to grow plant such as lettuce, basil or scallions.

- Improve system based on initial testing and prototype and design a larger hydroponic system that can handle 6 plants at a time. Making sure that system is modular to be expanded. (03/25/23)

- Make the first iteration of the 6-plant modular hydroponic system. (04/05/23)

- Re-design and iterate and create the final project of the hydroponic system. (04/15/23)